The first brake lining was created in 1888. The first asbestos brake lining was formally developed in 1908 after the invention slowly advanced over time. Because of its heat resistance, fire resistance, electricity resistance, tensile strength, and sound absorption qualities, asbestos was chosen for this project. The early 1900s saw the beginning of a serious examination of asbestos toxicity. Read More…

You only need to know one name for your friction material needs: Cook Bonding & Manufacturing. We have been working hard for over 3 decades and specialize in the manufacture of high quality friction materials, gear tooth facings, press blocks, and more.

ProTec Friction Group is a producer of friction components and forms. By combining our manufacturing expertise with our supply chain knowledge, we are able to bring friction solutions to our customers.

Cleveland Oak's friction material products division designs & manufactures friction products such as brake shoes, clutch facings, bands, disc brake pad products plus clutch pads. We keep metric & standard molded, sheet & woven friction materials in stock & perform friction materials bonding and riveting. In business since 1916, our high quality friction materials are economically priced as well.

At Fisher Barton’s Accurate Specialties, our innovative, integrated manufacturing supports our expertise in chill casting, centrifugal casting, spuncast gear blanks, continuous casting, and more. Fisher Barton delivers complete, Accurate Specialties branded, fully machined, ready-to-hob bronze gear blanks made to exact customer specifications. With us, you can guarantee quick turnaround times...

In business since 1732, The Rowland Company is a specialty distributor/fabricator of industrial power transmission components and friction materials. The company specializes in problem solutions tailored to our customer's specific needs from clutch sets and brake assemblies to couplings, gear boxes, variable speed drives and other related items, all designed to withstand rugged industrial use.

More Brake Lining Manufacturers

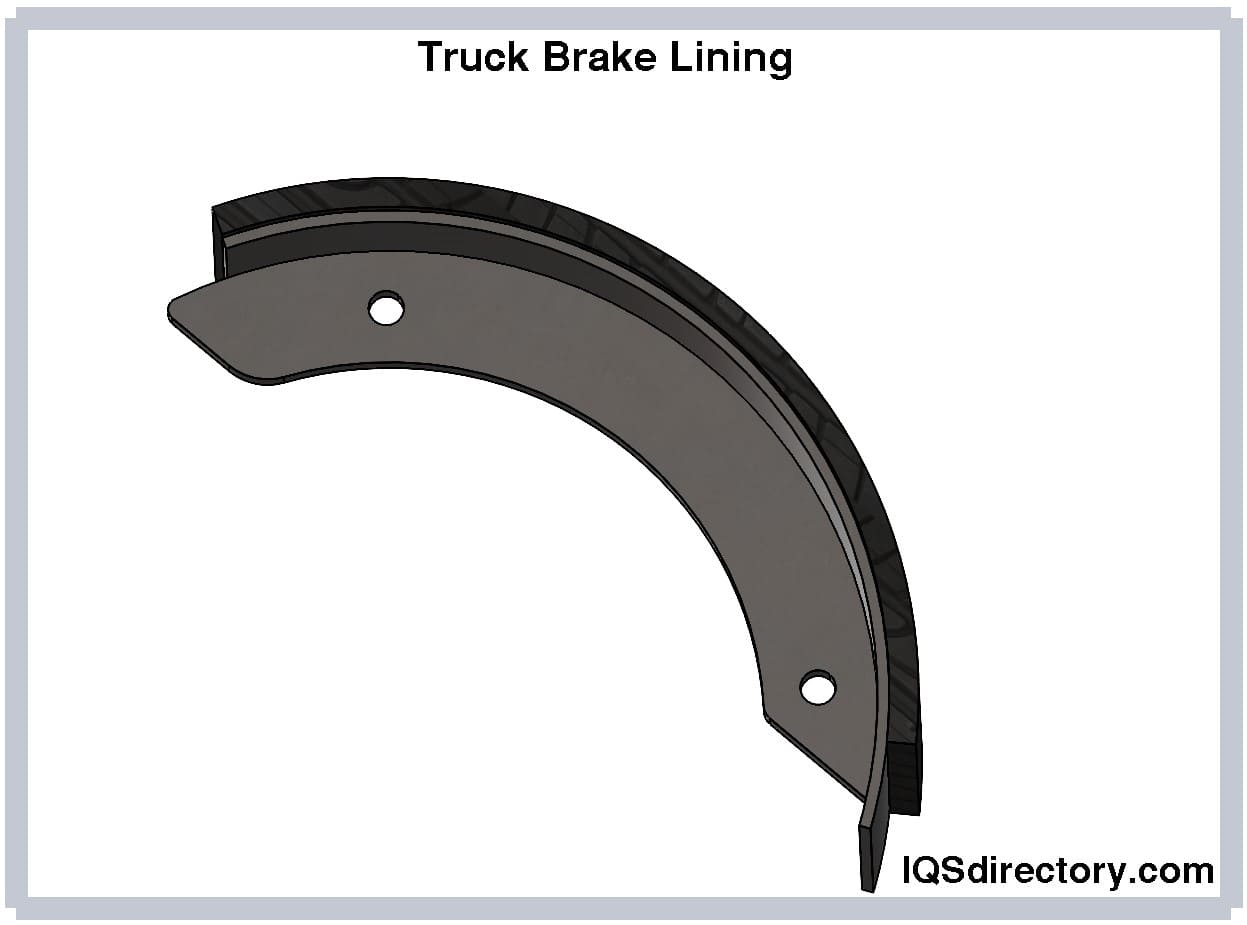

The first recognized asbestos-related fatality diagnosis was made in 1924, although the fiber was not completely outlawed until 2003. Numerous mechanical braking systems, such as those in bicycles, trucks, vehicles, tractors, other farming equipment, elevator safety brakes, and even the spindle brakes found within VCRs, use brake linings of diverse forms, sizes, and material compositions today.

Materials for Brake Lining

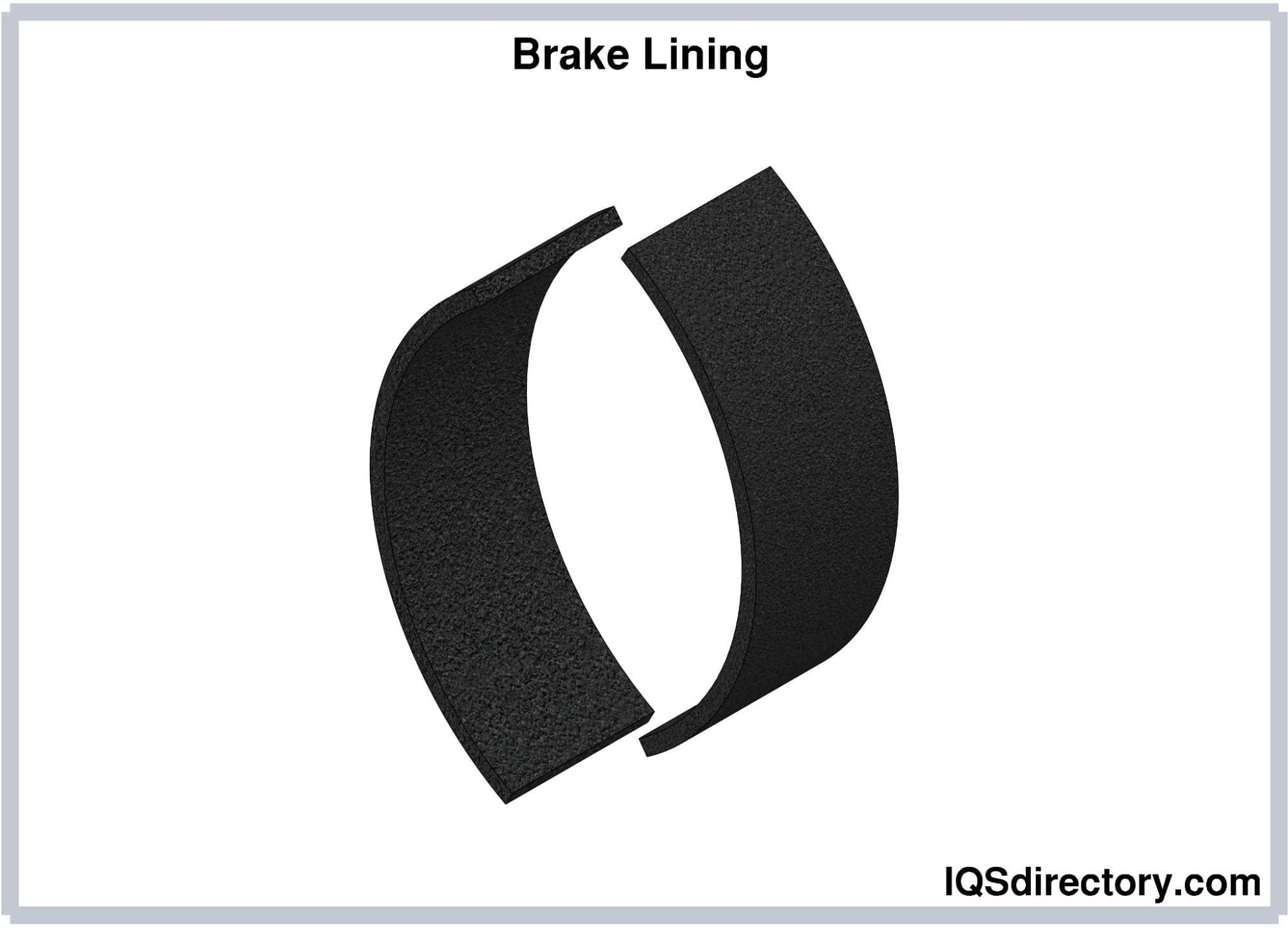

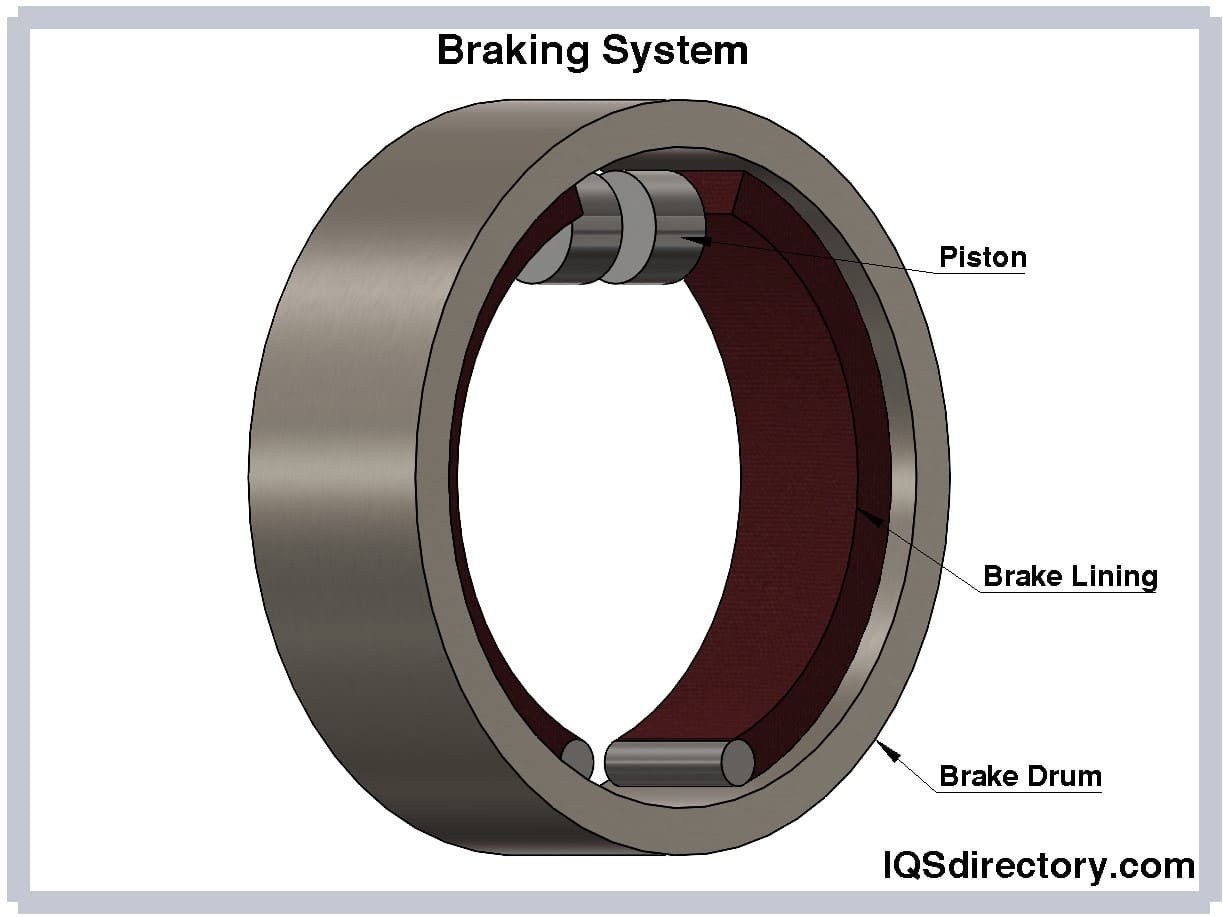

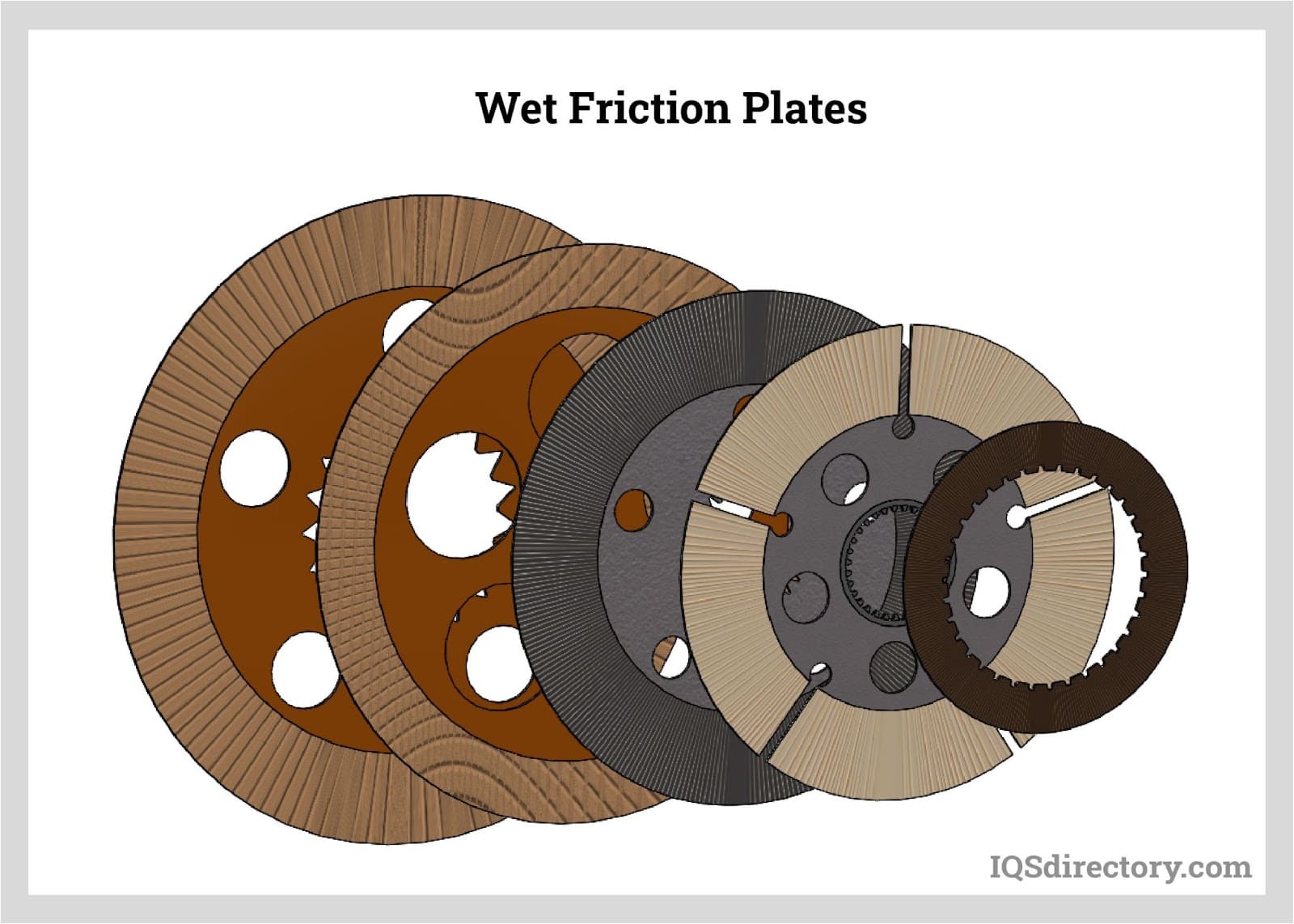

A part of braking mechanism systems is brake lining. Brake lining, which is composed of friction-causing materials, more commonly referred to as friction materials, helps slow or stop the motion of moving machines and vehicles. Similar to brake bands and brake blocks, brake lining, often known as brake pads, provides a barrier between parts like brake shoes and rotors. As a result, they increase friction and slow down contact while extending the system's lifespan by preventing premature component wear. In essence, they act as a safety net. Therefore, brake pads are essential to the braking systems' persistent condition.

Designing Brake Lining

Brake lining materials are attached to a metal or ceramic backing, similar to the brake shoe, using heat-resistant joints, heat-resistant rivets, or high-tech adhesives. Additionally, brake lining material always has a high coefficient of friction because the kinetic energy required during the braking process is transformed into thermal energy. Therefore, in addition to being rough or textured (friction materials), the materials used to create the materials must be strong and bear high heat and pressure.

A wide range of semi-metallic and non-metallic materials, including aramid fibers, carbon composites, cellulose mineral fibers, ceramics, chopped glass, copper fibers, and steel fibers, may be used by manufacturers to create brake linings. Although they normally operate with standardized compositions, manufacturers may combine friction materials with different compositions and thicknesses.

Due to the health risks asbestos exposure presents, such as the development of lung cancer, other lung diseases, or mesothelioma, friction materials are no longer primarily made of asbestos fibers. Some linings are made of tougher brake materials, but this is only smart if the clutch disks or drums that go with them are also robust and of excellent quality. If they are not, wear and tear could easily occur more quickly. Sometimes using soft, lightweight brake linings is preferable.

No matter the specifics of the lining that creates it, friction is necessary for all braking systems since it is the process that permits machinery and engines to slow down and accelerate efficiently. Therefore, it is crucial to pay attention to a few different things to maintain the braking system connected to a brake line, whether it be an elevator, tractor, car, or any other machine or vehicle.

Considerations When Choosing Brake Lining

To be able to maintain this friction coefficient over a wide range of heat values, brake lining should have values with high friction coefficients. The friction coefficient falls as the brake pads' temperature values rise. High-temperature resistance and long-term abrasion resistance are requirements for brake-lining materials. At the same time as they should not harm the brake lining, brake lining should wear out progressively and have a long service life.

- Brake lining must be quiet while rubbing (Because these sounds cause great discomfort in the future).

- Brake lining should not lose its braking qualities by glazing at high temperatures.

- Foreign substance resistance is required for brake lining.

- When rubbing, the brake lining shouldn't generate noise.

- Brake lining should have high friction coefficient values to maintain this friction coefficient.

- The brake lining must be waterproof to foreign substances, including water, dirt, and dust.

Types of Brake Lining

Ceramic Brake Lining

The name accurately describes what ceramic brake linings are. They have copper fibers added and are formed of clay, comparable to pottery. They are the most recent brake pads seen in the newest high-performance cars.

Lightweight ceramic brake linings guard against metal-to-metal wear. The dust does not adhere to the wheels or the vehicle. They last long and are quiet. They are also gentle on the rotor. The novelty and several advantages of ceramic brake linings make them the priciest product on the market.

Semi-Metallic Brake Lining

Up to 65% of the metal content in semi-metallic brake linings is metal. They are made of various metals, most frequently brass, copper, iron, or steel. They also have fillers and lubricants made of graphite. The strongest linings are semi-metallic. As a result, they can be more effective than other brake materials and will last longer than non-asbestos materials. This durability is because the metallic composition can dissipate that heat from the rotor. Semi-metallic brake linings are inexpensive, but they have the drawback of being noisier and producing more dust.

Choosing the Proper Brake Lining Supplier

To ensure you have the most positive outcome when purchasing brake linings from a brake lining supplier, it is important to compare several brake lining companies using our directory of brake lining suppliers. Each brake lining supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each brake lining company website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple brake lining businesses with the same form.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services