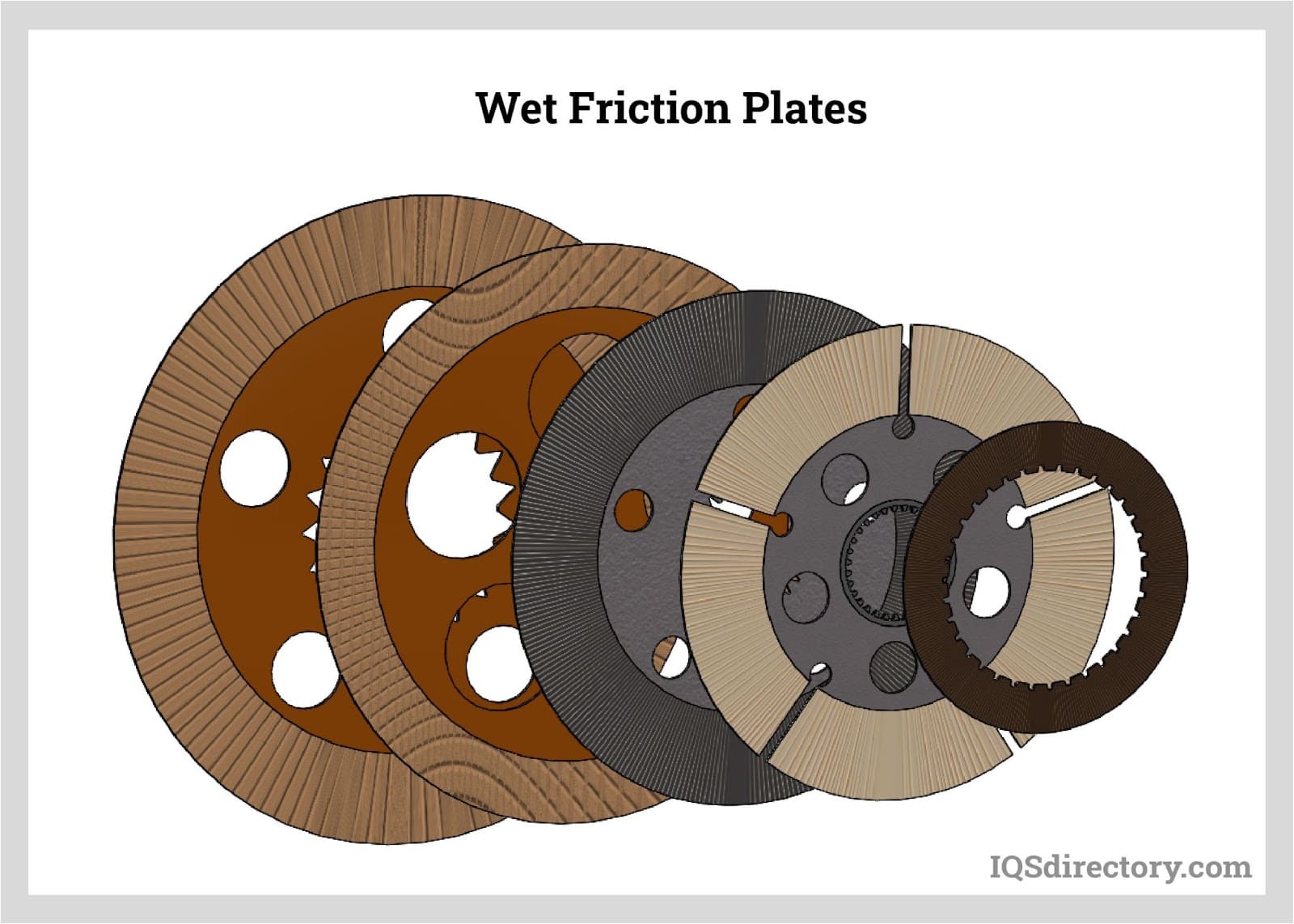

Friction discs are made of friction materials and bonded, usually with rivets, to a metal plate. These make up the disc brake pads of the brake component. The other parts of a typical disc brake include calipers attached to pistons and rotors which are responsible for motion. Read More…

You only need to know one name for your friction material needs: Cook Bonding & Manufacturing. We have been working hard for over 3 decades and specialize in the manufacture of high quality friction materials, gear tooth facings, press blocks, and more.

ProTec Friction Group is a producer of friction components and forms. By combining our manufacturing expertise with our supply chain knowledge, we are able to bring friction solutions to our customers.

Cleveland Oak's friction material products division designs & manufactures friction products such as brake shoes, clutch facings, bands, disc brake pad products plus clutch pads. We keep metric & standard molded, sheet & woven friction materials in stock & perform friction materials bonding and riveting. In business since 1916, our high quality friction materials are economically priced as well.

At Fisher Barton’s Accurate Specialties, our innovative, integrated manufacturing supports our expertise in chill casting, centrifugal casting, spuncast gear blanks, continuous casting, and more. Fisher Barton delivers complete, Accurate Specialties branded, fully machined, ready-to-hob bronze gear blanks made to exact customer specifications. With us, you can guarantee quick turnaround times...

In business since 1732, The Rowland Company is a specialty distributor/fabricator of industrial power transmission components and friction materials. The company specializes in problem solutions tailored to our customer's specific needs from clutch sets and brake assemblies to couplings, gear boxes, variable speed drives and other related items, all designed to withstand rugged industrial use.

More Friction Disc Manufacturers

The friction discs are used to slow or stop the motion of drive shafts which will in turn stop the wheels from rotating. As pressure is applied to the brake pedal, the calipers cause the discs to close around the rotors. This pressure can be a result of hydraulic, mechanical or pneumatic power depending on the design of the engine, but either way, when enough friction has been created, the rotors will stop moving.

The materials used in the construction of friction discs need to be durable enough to withstand the stress and tension of the friction process, as well as to maintain strength despite the high temperatures achieved. During the process of creating friction, a large amount of kinetic energy is converted into heat energy. This allows the drive shaft to stop moving, and the energy can then be dissipated as heat.

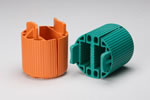

Disc design varies according to application and choice of brake material, but high quality construction will ensure longer lasting discs. Uneven wear or thickness of discs is responsible for juddering or engine vibrations, resulting in potential engine component damage or an unpleasant engine ride. Well made discs, which may be solid, slotted for ventilation or drilled for high performance vehicles, will wear at the same rate, allowing smooth breaking and gear changing even when they are almost ready to be replaced. Due to the high-stress nature of friction creation, friction discs will need to be periodically checked and replaced as the materials inevitably wear down over time.

Dust is created as the plates rub against each other and slowly break down their surfaces. This is a major reason why asbestos is no longer widely used for disc plate manufacturing or in clutch materials as asbestos dust is harmful to inhale. Other materials used for friction discs include woven fibers such as Kevlar or aramid and ceramic materials which are durable enough to withstand the pressure of friction but not so hard as to cause component damage.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services