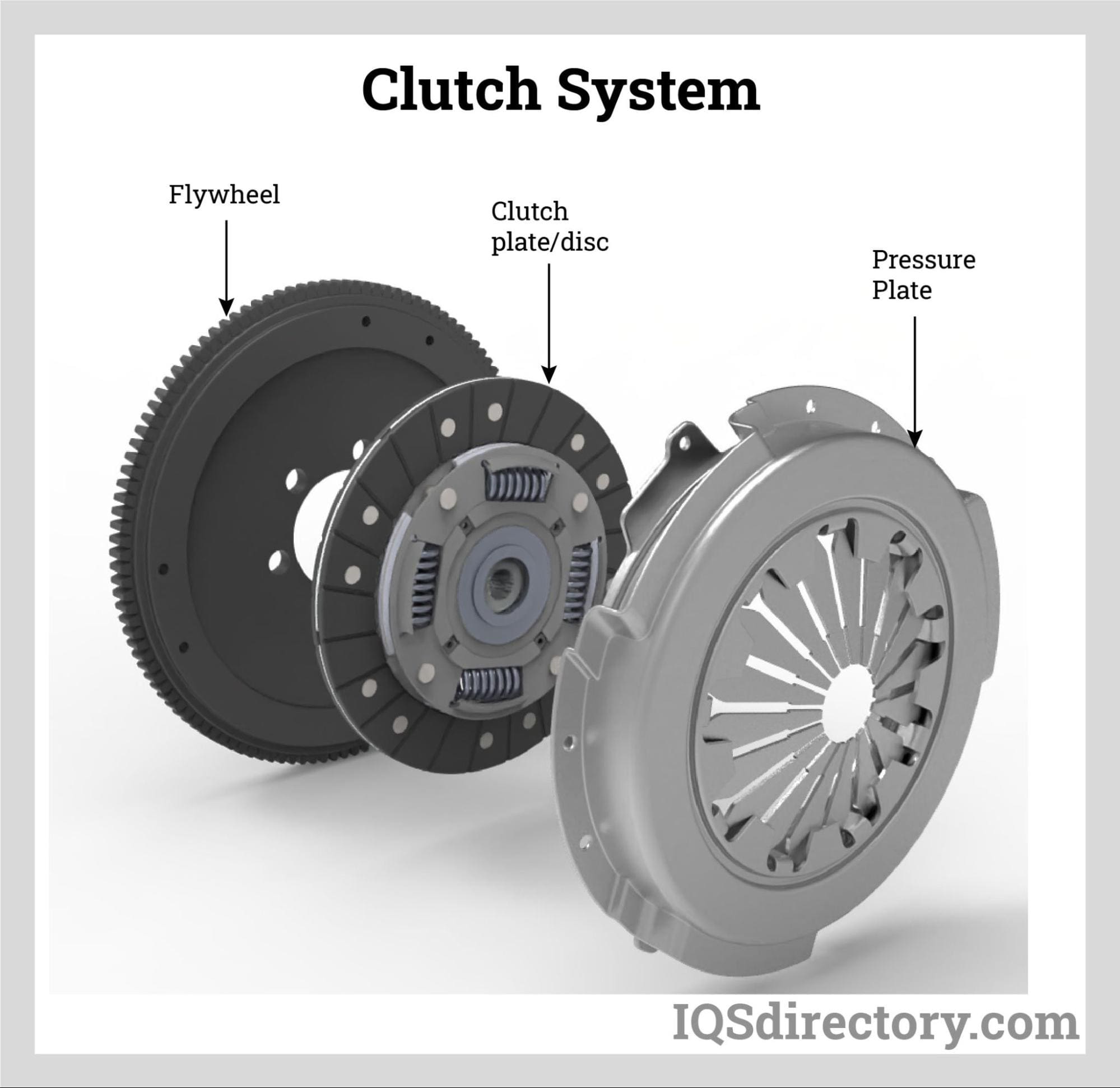

When two rotating friction surfaces are brought together and squeezed, they begin to rotate at the same speed due to the friction between them. This principle is the fundamental idea of a clutch. The area of a surface, the pressure placed on it, and the friction material between the two surfaces all affect how much friction there is between them. The pressure plate positioned on the transmission shaft serves as the driving member of a clutch, and the flywheel mounted on the engine crankshaft serves as the driving member. Certain friction plates are between these two parts, also called clutch plates. The clutch is the collective name for this component. Read More…

You only need to know one name for your friction material needs: Cook Bonding & Manufacturing. We have been working hard for over 3 decades and specialize in the manufacture of high quality friction materials, gear tooth facings, press blocks, and more.

ProTec Friction Group is a producer of friction components and forms. By combining our manufacturing expertise with our supply chain knowledge, we are able to bring friction solutions to our customers.

Cleveland Oak's friction material products division designs & manufactures friction products such as brake shoes, clutch facings, bands, disc brake pad products plus clutch pads. We keep metric & standard molded, sheet & woven friction materials in stock & perform friction materials bonding and riveting. In business since 1916, our high quality friction materials are economically priced as well.

At Fisher Barton’s Accurate Specialties, our innovative, integrated manufacturing supports our expertise in chill casting, centrifugal casting, spuncast gear blanks, continuous casting, and more. Fisher Barton delivers complete, Accurate Specialties branded, fully machined, ready-to-hob bronze gear blanks made to exact customer specifications. With us, you can guarantee quick turnaround times...

In business since 1732, The Rowland Company is a specialty distributor/fabricator of industrial power transmission components and friction materials. The company specializes in problem solutions tailored to our customer's specific needs from clutch sets and brake assemblies to couplings, gear boxes, variable speed drives and other related items, all designed to withstand rugged industrial use.

More Clutch Disc Manufacturers

Friction Clutch

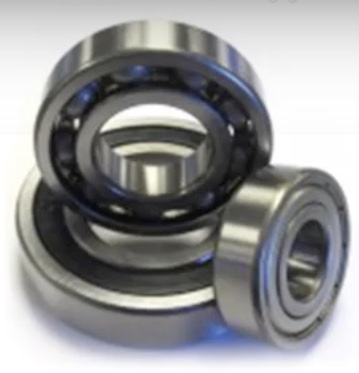

Engineers can engage and disengage the transmission and flywheel using a friction clutch. It is controlled by a clutch plate, pressure plate, and release bearing attached to a mechanical or hydraulic cable.

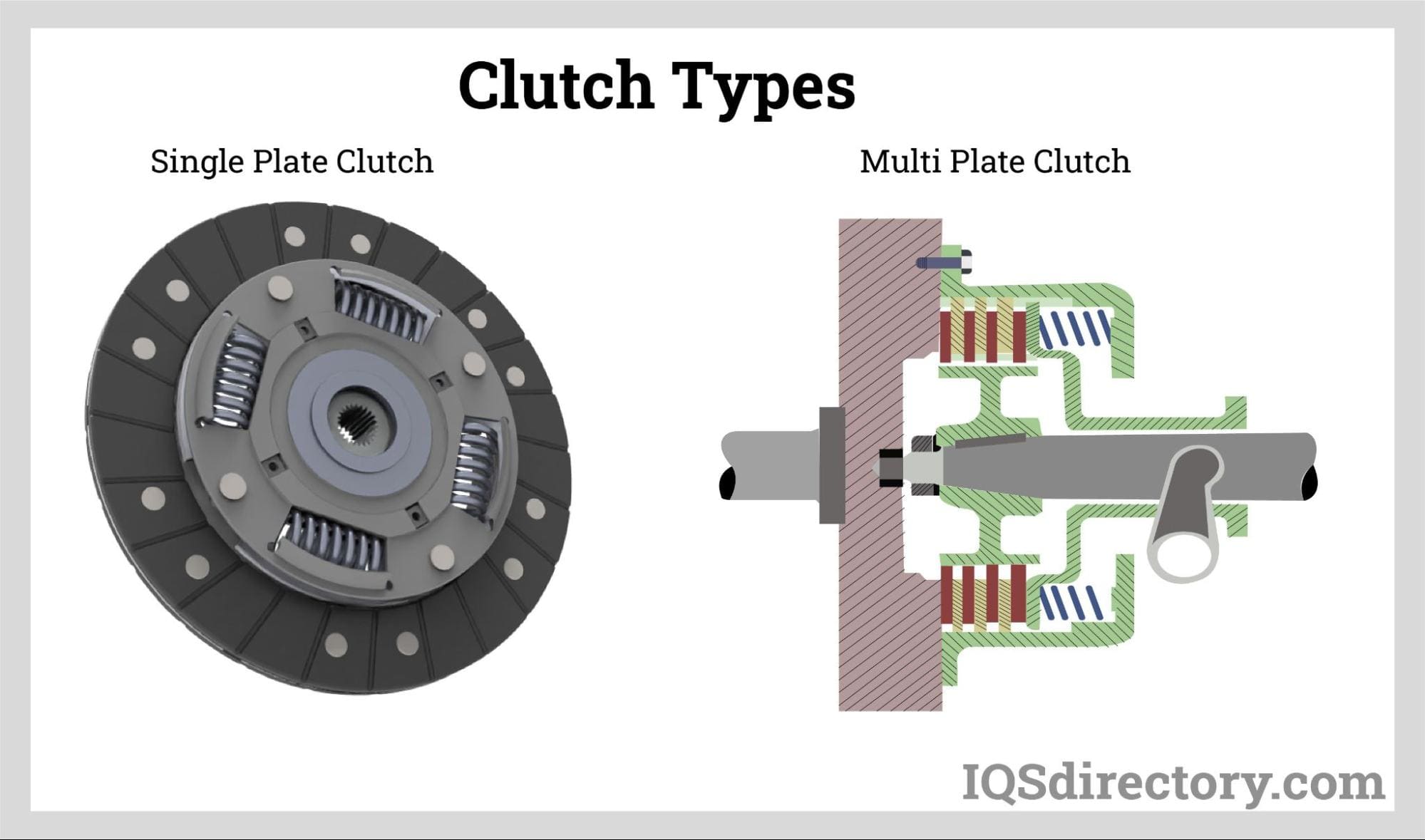

It is divided into two categories listed below:

Single Plate Clutch: For transferring engine torque to the input shaft, single plate clutches are primarily utilized in lightweight automobiles. According to the name of the clutch, there is just one clutch plate.

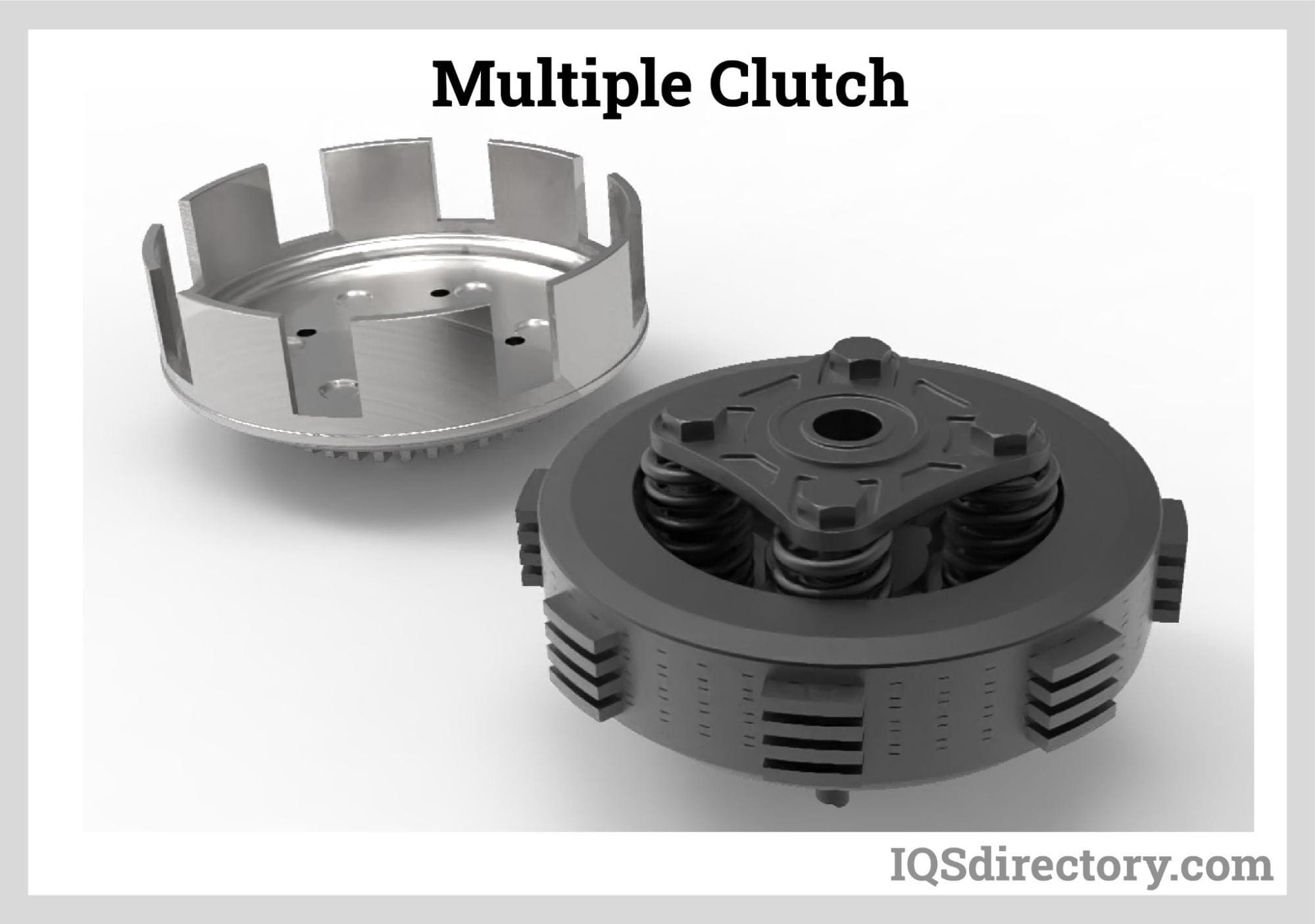

Multiplate Clutch: This type of clutch uses many clutch plates to transfer power from an engine's shaft to the vehicle's transmission shaft.

Clutch Discs/Plate

Automobile components called clutch discs and plates are essential for gear shifting in cars and large machinery. Clutch discs are rounded plates that join and separate the vehicle's engine and transmission input shaft. They are components of electric, hydraulic, pneumatic, and mechanical clutches. A brief disconnection between the transmission's input shaft and the engine permits the gears to shift when activated. In addition to the automobile industry, other sectors that benefit from clutch discs and systems include agriculture, construction, transit, defense, and shipping.

Materials Used for Clutch Discs

Materials for Powder Metallurgy

The maximum surface temperature, the maximum working pressure, the coefficient of friction at high temperatures, and the service life are all quite high.

It is not Metallurgical to use Copper-Based Powder

Wet testing of the friction surface is crucial. Iron-based powder non-metallurgical materials have a greater friction index and permissible working pressure than copper-based ones. Still, their wear resistance is lower, making them employed primarily for dry friction surface testing.

Products Made of Asbestos

The soil is on a steel or iron foundation plate, asbestos is added as a binder and filler, and the allowed working temperature is low.

Products Made With Paper

It is constructed from asbestos, fibrous materials, or combinations of the two to complement one another. Epoxy resin is then used to connect the material after adding fillers. This kind of substance is inexpensive, has a porous structure, good friction properties, and comparable static and dynamic friction indices.

Materials in Clutch Discs

Materials for Friction

To delay or lessen friction-causing action, friction materials—also referred to as brake materials or clutch materials—are pads or linings composed of rough or textured materials. Asbestos fibers were once the most widely used type of friction material. However, they are rarely utilized today because of their health dangers. For this use, asbestos fibers have been substituted with friction materials such as mineral fibers, chopped glass, cellulose, copper fibers, aramid fibers, steel fibers, ceramics, various carbon composites, and semi-metallic and non-metallic materials.

For various clutch systems, composites are made by combining friction materials. For instance, heavy-duty application vehicles like performance cars and trucks frequently use clutch systems with ceramic mix brake pads. Because of their exceptional strength, durability, superior heat resistance, and increased coefficient of friction, they are preferred for applications like these. Be aware that while producers and suppliers might give the general public descriptions of popular composites, they frequently withhold the precise composition of their friction material to compete with rivals.

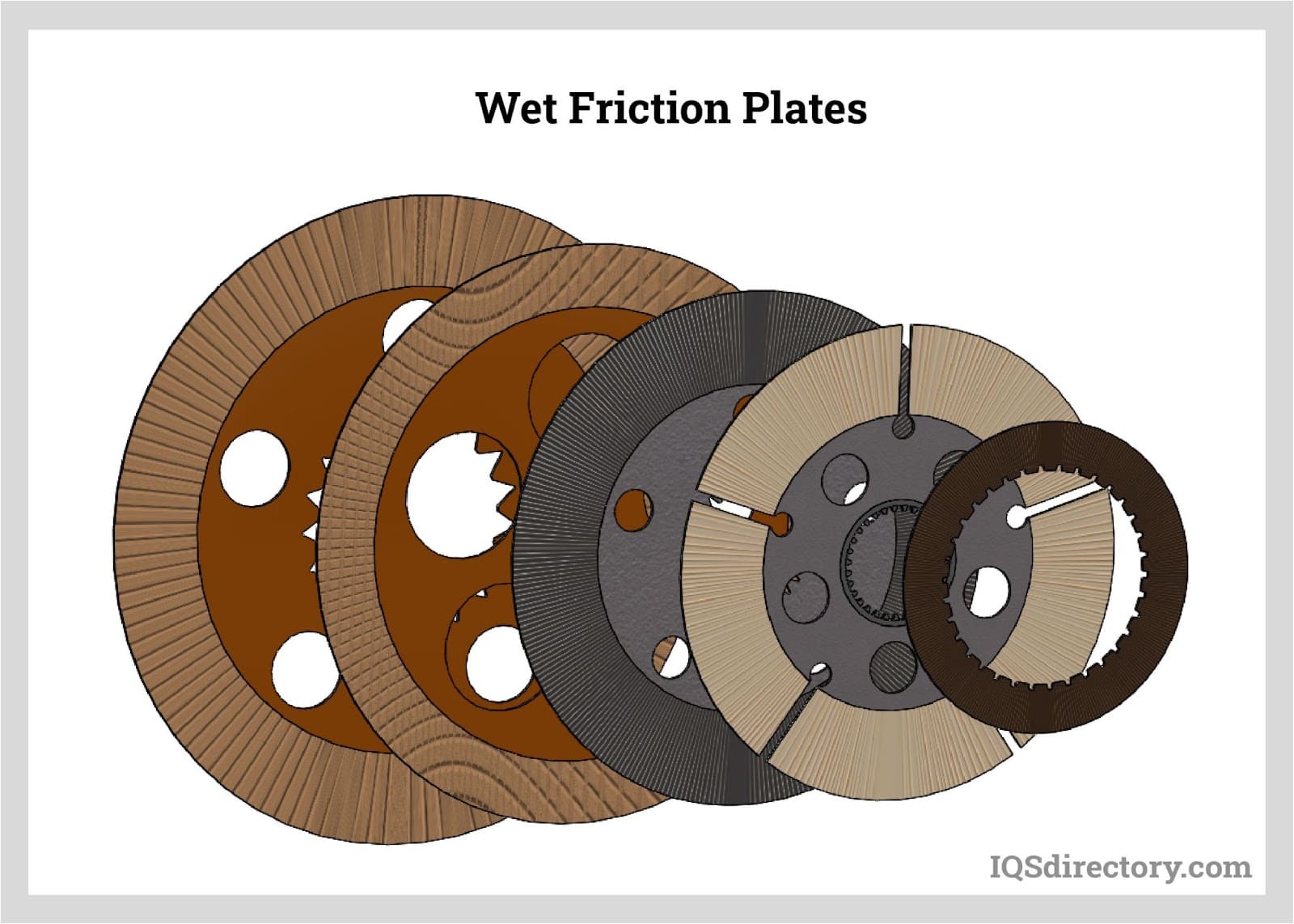

Lubricant for Cooling

Manufacturers can also reduce excessive friction by submerging the clutch in a cooling lubricant. This fluid allows smoother performances, keeps surfaces clean, and increases the lifespan of clutch systems in addition to keeping the clutch cold. Keep in mind that wet clutches are those that employ lubrication, while dry clutches are those that use friction materials. Wet clutches tend to lose energy and can be fairly slippery, but dry and wet clutches offer advantages. However, manufacturers can stack many clutch discs in one system to compensate for this slipping and boost friction.

Considerations When Choosing Clutch Discs

Buyers of clutch discs need to consider a few distinct application-related aspects. These include desirable dry or wet clutch systems, maximum pressure allowances, power, torque rating, and rotational speed. In addition, owners of clutch discs must be aware of a few signs and aggravators of unhealthy discs after making their purchase.

For instance, the clutch disc needs to be changed if the clutch's grip starts to slide. Additionally, using the clutch while quickly increasing the engine speed will wear down the disc. Finally, because different automobile models occasionally position the clutch disc in different locations within the engine, clutch disc maintenance varies from car to car.

Considerations When Choosing Clutch Discs

Buyers of clutch discs need to consider a few distinct application-related aspects. These include desirable dry or wet clutch systems, maximum pressure allowances, power, torque rating, and rotational speed. In addition, owners of clutch discs must be aware of a few signs and aggravators of unhealthy discs after making their purchase. For instance, the clutch disc needs to be changed if the clutch's grip starts to slide. Additionally, using the clutch while quickly increasing the engine speed will wear down the disc. Finally, because different automobile models occasionally position the clutch disc in different locations within the engine, clutch disc maintenance varies from car to car.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services